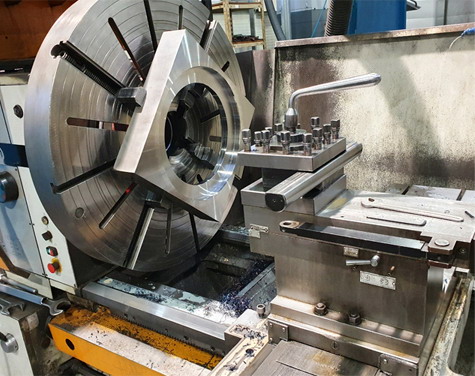

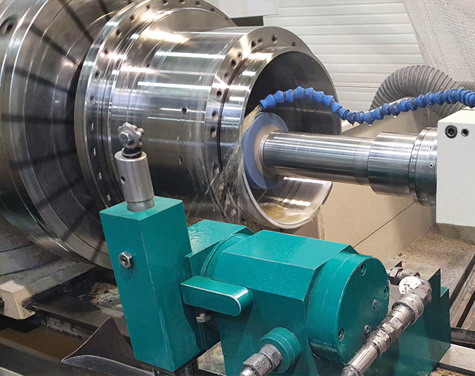

We specialize in piece and small series metalworking. The subject of our activity is turning, milling, surface grinding, round grinding, hole grinding and horizontal drilling. We produce various machine parts and units by conventional or CNC metalworking according to the customer’s production documentation. We cooperate with proven, certified companies on prescribed heat and/or surface treatment of metals.

We supply machine components and accessories to leading Czech and Swiss machine tool manufacturers.

We are able to supply individual parts or assembled and tested assemblies.

We produce aids, jigs and fixtures according to the drawing documentation supplied.

As part of the group’s cooperation with Královopolská slévárna, s.r.o. (the foundry), we offer the provision of sets of castings and their machining.

Static castings are in the range of 10 - 4500 kg. Their widths and lengths are 100 to 4000 mm, the height 2000 mm.

We also offer centrifugal casting of pipes, bushings, flanges, bimetallic pipes, etc.

Casting into ceramic moulds 5 - 250 kg. UNICAST licence.

The company’s basic offer includes 150 types of cast materials according to world standards:

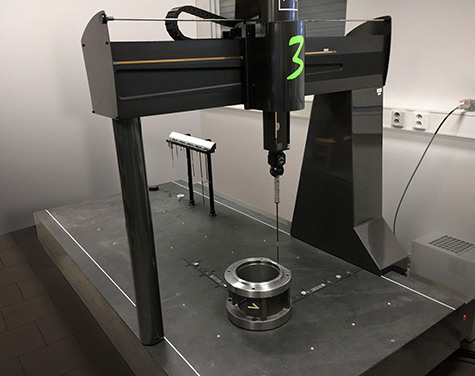

We can produce measuring jigs, limit calibres, roller calibres, conical calibres, templates, mandrels, roller gauges (range 1 - 20 mm), axles, shafts and special gauges.

At the customer’s request, we can provide a gauge with a certificate from the certification laboratory of me-trology.

Inter-operational and output inspection of manufactured parts takes place on a 3D coordinate measuring machine ABERLINK ZENITH 3 CNC.

We supply customers with measuring protocols for manufactured components in written or electronic form.

| Type of lathe | Model | Max. turning diameter | Max. diameter above support | Max. length | Note |

|---|---|---|---|---|---|

| CNC | SA89CNC | 550 mm | 890 mm | 2 000 mm | face place 630 mm, steady rests |

| CNC | S80 PRIM | 430 mm | 680 mm | 750/1 000 mm | 3 driven tools |

| CNC | Masturn 70 | 700 mm | 430 mm | 2 000 mm | |

| Centre | CU1000 | 1090 mm | 690 mm | 4 000 mm | face place, steady rests |

| Centre | S80 | 800 mm | 380 mm | 1 600 mm | face place, steady rests |

| Centre | SV18RA | 355 mm | 220 mm | 1 000 mm | |

| Centre | SN55 | 500 mm | 320 mm | 2 000 mm |

Dear Business Friends,

The company Ergozet s.r.o. was established in 2004 on the grounds of Zbrojovka Brno, with connections to its production programme and its long years of experience in metalworking.

Ergozet s.r.o. built a modern production plant at the Černovice Terraces industrial zone in Brno in 2010.

The company is engaged in the production of machined parts, with the option of complete subsequent as-sembly. It employs reliable professionally trained staff. It uses attested technologies and materials and guarantees product quality and agreed deadlines. Your order will be managed by a team of experienced and qualified experts from our trade and technology department. The company also has the necessary production software for planning piece and small-series production. Great attention is devoted to quality control here by an experienced metrologist. The company can issue measurement protocols in accordance with the requirements of the customer.

In 2010, the company received a CSN EN 190 9001:2009 Quality Management System Certificate on the basis of the results of a certification audit for the following processes

We perform: mechanical production, metalworking, metal machining, turning, milling, boring, assembly, grinding, surface grinding, round grinding, hole grinding, CNC machining, 5-axis machining, job-work, fix-tures, prototype production, prototype parts, prototype components, single-purpose machines, clamping tools, measuring devices, castings, the machining of castings